Do-it-yourself greenhouse from a profile pipe

Content:

When you want to build a greenhouse or greenhouse on your summer cottage, of course, the question arises: what material should be used? In this article, we will consider the self-made construction of a greenhouse made of durable material, namely from a profile pipe. With its help, it is possible to make a strong frame that will serve you for more than a decade. On social networks, it is possible to find a large number of recommendations for assembling such a structure as a greenhouse from pipes. However, most of the craftsmen characterize the process of construction from pipes, but not profile. In this article you will find information on how to make a greenhouse out of a pipe with your own hands.

Briefly about the construction of a "greenhouse of pipes"

You need to know that the profile pipe, unlike the usual specimen, has the shape of a rectangle or square.

Despite the light weight, this material is quite sturdy. If you expect to make an arched greenhouse, then we recommend using a forty by twenty profile. For lintels, it is recommended to use a pipe with dimensions of twenty by twenty.

The advantages of a profile pipe are listed below:

- has served for more than a dozen years.

- a wide variety of surface selection.

- installation is not difficult.

- fastening is not difficult.

- the ability to make the construction of various figures.

The only inconvenience is the bending of the material. With this option, it is necessary to correctly bend the only pipe, then apply it as a template. It must be filled with sand in advance.

Manufacturing of this structure

A couple of versions of curly greenhouses are known, but we thought to survey the establishment of an arched greenhouse. If there are little skills of similar processes, then there should not be a huge amount of trouble with the installation.

In the process of selecting a site for placing a greenhouse, it is necessary to take into account the required amount of light, therefore, the greenhouse should be located to the south side. Surface drops should not be more than ten centimeters.

To build arches, you need to purchase a profile with a section measuring twenty by forty, take ten copies of a profile pipe at once. The approximate length of the profile pipe should reach five point and eight tenths of a meter (it is possible to cut it off immediately upon purchase, or purchase six-meter shaped pipes). To decorate the arches, it is advised to use a tool called "pipe bender", if you make it yourself, then it will be problematic to get strong material.

For the frame jumpers, it is necessary to prepare a profile with a section of twenty millimeters by twenty millimeters, purchase forty copies at once. The length of the material should be up to sixty seven centimeters.

Use stakes and sturdy twine to mark the greenhouse under construction. To get a level greenhouse, you need to check the diagonal markings.

Dig a pit eighty centimeters deep, then place a cement mortar in it, approximately to the elongated bottom, the height of the excavated pit should reach fifteen centimeters.

At a new level, the transverse bases are welded to the longitudinal bases. To give strength and strength, it is advised to use corners made of metal.

Put bricks under the base, if there is a desire for masonry, it is possible to make a small ditch.

Immediately before making the frame, it is necessary to lay out the polycarbonate sheets, place the arcs on top and outline them with a felt-tip pen. It is possible to cut off the material with the help of a sharp construction knife, while not touching the additional two centimeters space.

When the solution completely hardens, it is worth starting the installation work from the frame of the profile pipe. It is necessary to weld the arch number one to the elongated bases.

It is worth mentioning that the installation of the arch under the first and last numbers is considered the most important process, therefore it is advised to use a plumb line.

With the help of jumpers, the remaining parts are welded in turn. Masters advise to start welding the arcs to the top of the jumpers. After that, install the last arch, then it is necessary to weld the end jumpers made of profile material with a section of size twenty by twenty, because they have no significant weight.

Polycarbonate is attached to the structure using specialized self-tapping screws with washers. Immediately before sheathing, the protective coating must be removed from the sheets. The first copy should go beyond the boundaries of the structure, by about fifteen centimeters.

After fixing the polycarbonate, it is necessary to cut off the holes for the windows and doors. All joints must be covered with a cloth with silicone.

The duration of this self-made structure reaches more than ten years. At the same time, a greenhouse made of pipes does not need any agricultural technology.

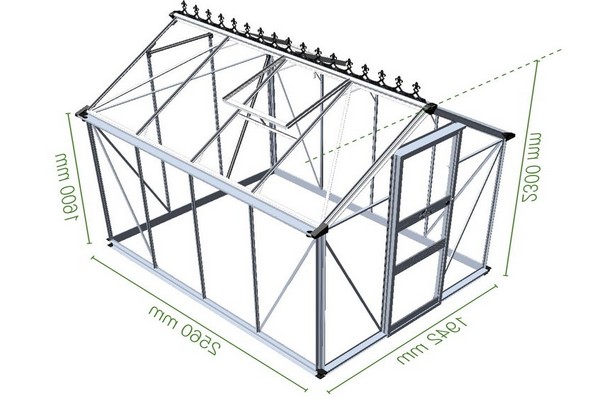

Drawing of this structure

When preparing a greenhouse structure scheme, it is necessary to take into account that the pipe has ordinary dimensions from three to twelve meters. Therefore, you need to ask the seller for this small nuance. This will allow you to get away from unnecessary costs and operate without unnecessary trimming.

Note! The cross-section of a pipe from a profile for basic elements should be twenty by forty, and another twenty by twenty for connecting parts.

It is possible to apply the following information on the drawing:

- the foundation.

- about vertical racks.

- about the structure of the roof.

- about the upper strapping.

- about the doors.

- about the windows.

- about spacers.

To begin with, you need to choose with the space between the vertical uprights. Masters advise sizes of one hundred centimeters. With the option when the greenhouse must be covered with dense matter, then the space can be reduced to sixty centimeters. This is required to reduce the load on the pipe. If it is necessary to increase the space, then it is necessary to purchase auxiliary parts.

A different method must be used to make an arch-shaped greenhouse. Because here it is necessary to correctly bend the pipe from the profile material at the correct angle. If it is assumed that the height of the greenhouse will reach two meters, then it is necessary to buy a twelve-meter pipe. The space between the arcs, it is advised to make no more than one hundred centimeters.

All arcs are fixed to each other; in order to secure the building from all sides, it will be necessary to use profile materials. In the family, mention the auxiliary struts on the parts.

Do not forget that, if desired, it is possible to make various parts from the pipe, therefore it is known about such an opportunity as creating a lean-to, in the form of a triangle or a ball for a greenhouse.

You most likely realize that the construction will be quite heavy, which means that it is necessary to make a base. The foundation is prepared at the request of the owner of the summer cottage. It is advised to immediately place the anchor in the cement solution, to which the frame for the fortress is welded.

A greenhouse from pipes is assembled according to the following principle:

- for vertical construction projects, it is necessary to cut a pipe from a profile material of the required dimensions.

- weld vertical posts to the base, while using a tool called "building level".

- at the top of the construction it is necessary to fix the outline.

- take measurements and cut out details for vertical posts.

- combine and strengthen all the racks with cross beams.

- make a door and install it in the planned place.

One part of summer residents and farmers prefer making a frame on the ground, after which it is strengthened on the foundation. To avoid irregularities, these processes must be done exclusively on a flat area.

For hand-made production greenhouses in the form of an arch of their pipes made of shaped materials, it is necessary to use a tool called "pipe bender". In its absence, the following processes must be performed for bending:

- cut a part of the required size.

- to make saws.

- bend the pipe.

With this option, the craftsmen are advised to start assembling from both sides. This allows you to get the fortress of the structure.

Immediately after installing the frame, it is necessary to strengthen the polycarbonate. However, a couple of pitfalls are known here, which are listed below:

- the top side is the one with the protective layer.

- it is necessary to attach the sheets using self-tapping screws with rubber caps.

- the sheets are fastened together with plates, made of metal.

- a sealant is applied to the joints.

- after strengthening the material, remove the protective coating.